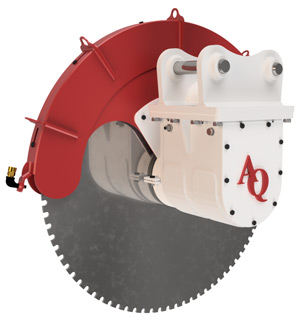

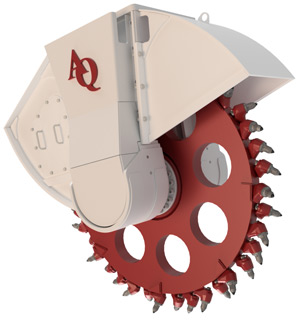

Antraquip offers carbide rockwheels and diamond saw attachments for excavators of all sizes and various applications. Antraquip's carbide rockwheels offer a cutting solution for soft to medium hard rock and concrete cutting applications with a minimum width of roughly 2 inches (50mm) while the diamond saw rock wheel offers a cutting solution for hard rock that other mechanized methods of cutting simply cannot handle. The diamond saw rock wheel attachments, also known as the AQD Series, can cut the hardest rock including granite, basalt, etc. as well as reinforced concrete.

Identifying the correct model for your excavator is an important step. Please contact Antraquip for assistance with choosing the right rock wheel for your specific application.

Common applications for Antraquip’s Carbide Rockwheels and Diamond Saw Attachments: